What the cost of the plastic mold contain?

The development of a set of plastic mold mainly includes the following contents:

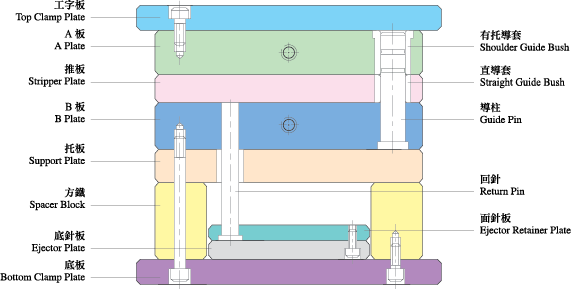

1, The cost of the mold, mold material is usually S45C or S50C, every country has several well-known professional production mold suppliers, you can purchase to them, Generally, we used the standard mold base to built the mold. But for the product size being too large,which is beyond the scope of the standard plastic mold frame size requires additional order, such as the size of the commonly used Edge Gate System ranges from 150mm x 150mm(series 1515) to 600x800mm(6068 series), if the size of plastic mold base is beyond the 600mm x 800mm requires additional order, cost generally 2-3 times that of the standard mold.

2, How the cost of the core and cover material was, which according to the properties of different injection molding material and plastic mold life choosing different steel. Commonly used plastic mold steel are:718,718H,S136,8407,NAK80,P20,2083,etc.

How to choose the plastic mold steel?

(1) Related to the characteristics of the plastic material.

Such as in the production of PVC plastic will produce corrosive acid gases. Plastic Mold is easy to be rust if using ordinary steel, so it needs to choose the anti-corrosion steel, such as 2083, S136H, etc

(2) Related to the requirements of the plastic product.

There are some very highly transparent products, such as optical lenses, glasses lens, which needs the steel has excellent polishing properties, such as S136, if choosing wrong material, when the plastic mold polishing into a mirror finishing, you will find obvious plastic mold texture, which can’t be eliminated by polishing, and can’t meet the requirements of the plastic mold making products.

(3) Related to plastic mold life.

Even the same brand of steel, the price will be different, of course, the material quality with the high price will be better, if you don’t need high plastic mold life, you can choose the cheap steel.

3, The cost of the hot runner system.(If the plastic mold need the hot runner system)

4, The cost of the copper. (Copper production is mainly used for the production of electrodes and some parts which require rapid cooling)

5,The cost of slide and lifter.

6, The cost of machine processing, such as Lathe processing

Milling machine processing

Grinding machine processing

CNC machine processing

EDM electrical discharge machining

Wire cut processing

Fit the plastic mold

The price of machine processing is generally calculated according to how much money per hour, such as CNC machining from $10-$11 per hour in Shenzhen, China.

7, The cost of plastic mold design.

8, The management of the factory cost includes the necessary cost on this project which the labor of manager and other engineers follow-up services. The bigger factory in this area the cost is higher, the factory is smaller that the less cost.

9, The profit of the factory.

The price of a set of plastic mold cost roughly determined by these factors.

Get A Free Quote