ALUMINUM & ZINC ALLOY DIE CASTING PARTS AND MOULD MAKING

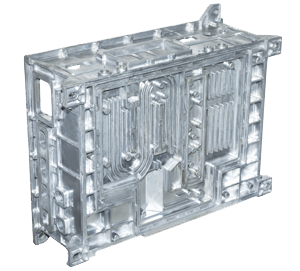

If you are looking for aluminium & zinc die casting Tooling and products manufacturer, Imould Technology Co., Ltd is your best choice. We are the expert of aluminium & zinc die casting process in China. Our engineers have rich experiences and know-how with so many years of practising and producing in aluminium & zinc die casting mould design and making field.

Provide professional skill suggestions in mold design to our customer that can reduce risk and save more time in trial mold step, special in saving cost. Keeping high quality aluminum die casting parts and producing effective is our mission.

Our service is in precise tooling design, tooling manufacture, injection moulding and die casting, which will be requested by new energy, security, automotive parts (such as carburettor casting parts ) and telecom.

Our greatest strengths: We are very good at making complex products. Most of the time, we can do complex moulds and products which are other factories can’t do it.

For a new project, we will give customers a lot of practical advice to help them optimize product design and save costs.

For more details about aluminum die casting products, try to check out below:

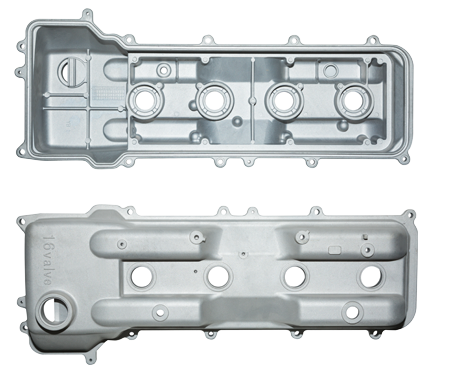

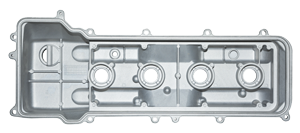

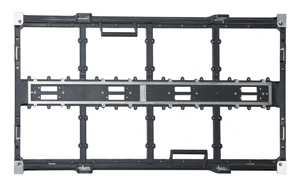

Automotive Field

Products include traditional auto parts ,new energy auto parts and lightweight auto structural parts;

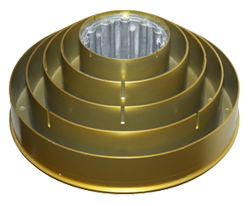

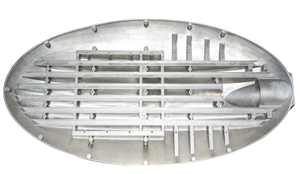

Industrial Equipment

Products include Oil cylinder, Engine assembly, Mechanical parts, etc.

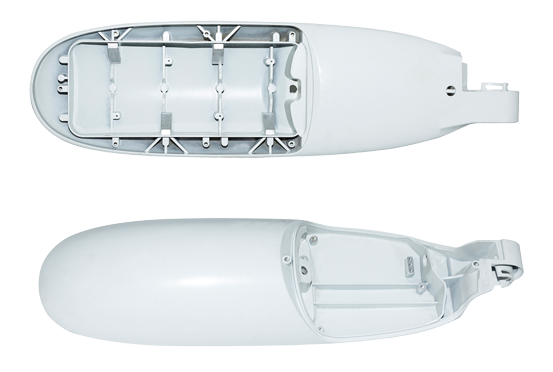

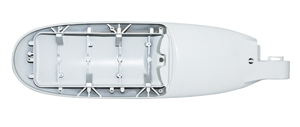

Municipal Engineering

Products include Traffic light, Street lamp, Park bench, etc.

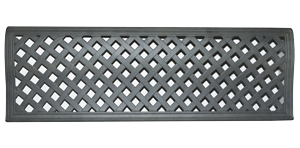

Other Fields

Products include wave filter, microwave equipment, Movie props, and Display stand, LED Light, etc.

Our service is in precise tooling design, tooling manufacture, injection moulding and Aluminium & Zinc die casting

Imould Tech knows all your needs about quality and delivery.

Start with a free project reviewProduction Strength

1) Own 17 sets of various die casting machines (100T-2000T);

2) Annual inputs of aluminum materials for production is more than 10,000 tons;

3) With more than 100 multiple series of products, mainly in fields of new energy, security, automotive parts and telecom;

4) With the smallest unit of 0.008KG, and the largest unit of 42.5KG;

Our aluminum & zinc die casting facility consist of

No. | Equipment | Quantity | Secondary Process | Finishing Available | Quality management section |

1 | Zitai Die casting Machine 100T | 1 set | Degating | Polishing | APQP |

2 | Zitai Die casting Machine 150T | 2 sets | Drill | Chromate Conversion | PPAP |

3 | Zitai Die casting Machine 250T | 4 sets | Tapping | Plating | SPC |

4 | Zitai Die casting Machine 350T | 1 sets | CNC Machine Processing | Powder coating | MSA |

5 | Zitai Die casting Machine 420T | 1 sets | FMEA | ||

6 | Zitai Die casting Machine 550T | 1 sets | |||

7 | Zitai Die casting Machine 650T | 1 sets | |||

8 | UBE Die casting Machine 800T | 2 sets | |||

9 | Toshiba Die casting Machine 1250T | 1 sets | |||

10 | Zitai Die casting Machine 1600T | 1 sets | |||

11 | UBE Die casting Machine 1650T | 1 sets | |||

12 | UBE Die casting Machine 1850T | 1 sets |